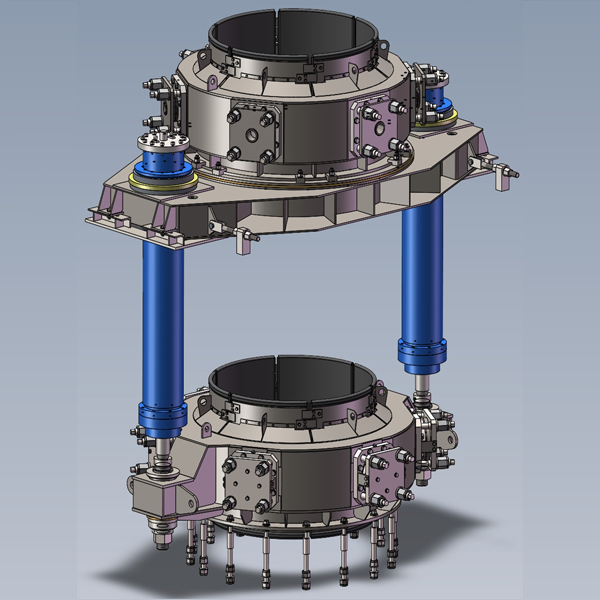

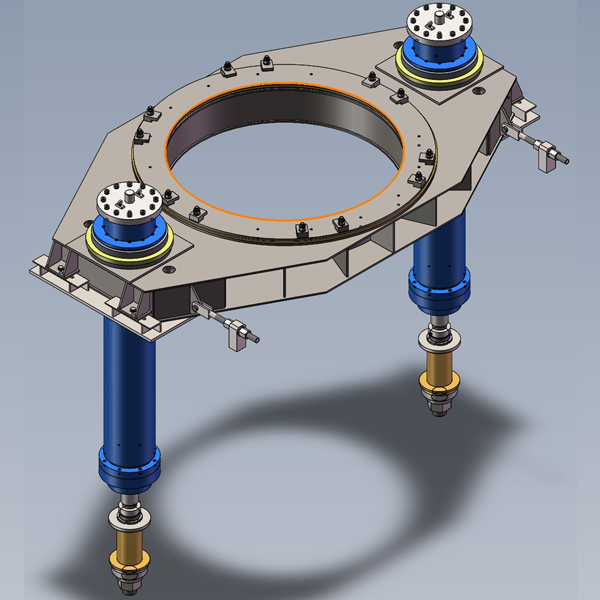

The electrode lifting and slipping system adopts a “hanging cylinder-upper brake fixed” structure, which is simple in system and small in space. The overall design of the upper brake and civil engineering platform is fixed relative to the oil cylinder body. The lower brake and electrode movement are driven by the extension and contraction of the hydraulic rod. By controlling the opening and closing of the upper and lower brake, it can achieve the electrode slipping.

During normal operation, the upper brake is always open and the lower brake is always closed. The upper brake is tightened by hydraulic pressure, and is reset and opened by the elastic force of the disc spring. The clamping force of the lower brake on the electrode relies on the elastic force of the butterfly spring. When releasing the electrode, hydraulic pressure is used to overcome the elastic force of the spring, achieving the release and clamping action of the brake on the electrode. The electrical interlocking of the upper and lower brake cannot be opened at the same time.

The slipping of the electrode can be used in three forms: automatic, manual, and machine side. The upper and lower brake pressure monitoring signals are connected to the control system of the submerged arc furnace. The slipping volume can be adjusted from 20-50mm each time.